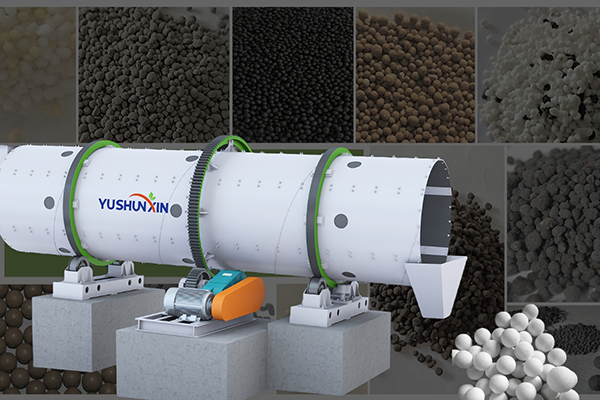

At fertilizer production drum granulator Suitable for the production of complex fertilizers of cold, hot and low, medium and high concentration. Hot and cold granulation process The drum granulator refers to two methods of forming granules of fertilizers under different temperature conditions. These two methods have different applications and advantages in the production process:

Drum granulator of cold granulation

Cold granulation in the production of fertilizers is a granulation process at room temperature. This method does not require the heating of the material. For the formation of particles, it is mainly based on mechanical force and binder material.

Features include:

- 1

Suitable for heat -sensitive materials: Some ingredients can decompose or lose activity at high temperatures, Therefore, cold granulation can maintain the effectiveness of these ingredients.

- 2

Energy saving: since heating is not required, Energy consumption is low.

- 3

Suitable for simple processes: usually used to produce some fertilizers, not requiring strict requirements for the size of particles or strength.

Drum granulator for thermal granulation

Thermal granulation in the production of fertilizers involves heating the material to a softened or partially molten state. Then the granules are formed using the drum -granulation mechanism.

Features of this process include:

- 1

Improved pellet quality: With thermal granulation, more rounded, dense and durable pellets. Increasing the efficiency of fertilizers.

- 2

Better suited for certain chemical reactions: Some types of fertilizers require chemical reactions at high temperatures to increase their effectiveness or stability.

- 3

Fast drying: since the granules are formed at high temperatures and the moisture content is reduced, The subsequent drying process can be reduced.

The choice between cold or hot granulation usually depends on such factors, as requirements for the final product, characteristics of raw materials and production costs. For example, In complex fertilizers (Such as nitrogen, phosphorus and potassium complex fertilizers) The process of thermal granulation is often used, to ensure the uniformity and stability of particles. Some organic fertilizers may be subjected to cold granulation to protect the activity of organic ingredients.