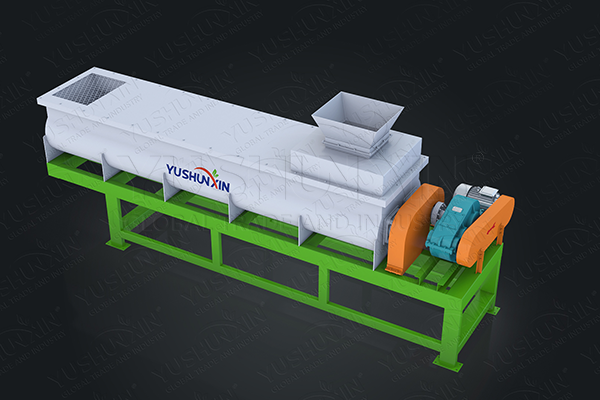

Twarge mixer – This is a mixing device, having two stirnels. Each axis has a blades or other types of mixing elements. This design allows you to effectively increase the efficiency and uniformity of mixing, especially suitable for processing materials with high viscosity, a significant difference in density or containing large solid particles. The use of a double -sized mixer is the following:

Building materials: In the manufacture of dry building mixtures, cement mixtures, thermal insulation solution, waterproof materials and other products, A double -shit mixer with blade screws provides quick and uniform mixing.

Chemical industry: Used to mix various chemical raw materials, suspensions and homogenization. For example, Plastic granules, Fertilizers, pigments, adhesives, etc..

Food industry: A double -sized mixer can process such foods, Like dough, minced meat, syrups, etc., Providing the uniformity of the texture of the mixture.

Pharmaceutical industry: It is used to mix various powders and viscous materials in the production process of drugs, guaranteeing the uniform distribution of components.

Ecological industry: Mixing and stabilization of chemicals in environmental projects, such as sedimentation processing and hard waste processing. And cleaning suspended substances in wastewater.

Feed production: Mixing various feed components, Such as grain, additives, nutrients etc., for the production of homogeneous animal feed.

Powder industry: Used to mix various powders and particles, such as dry colors, Metal powders, etc..

Energy industry: In the production of biomass energy, it is used to mix the source materials, such as wood chips, straw, etc., In order to improve the quality of biofuel.

A double -sized mixer is usually developed taking into account high shift loads and complex mixing tasks. It effectively processes materials with high viscosity, lumps prone to the formation of lumps or requiring quick mixing. Various designs of double -shaft mixers (Types of blades, way of their placement, rotation speed, etc.) can be adapted to specific Characteristics of materials and applications requirements.