What is the diameter of the granulator SXYZ-3600?

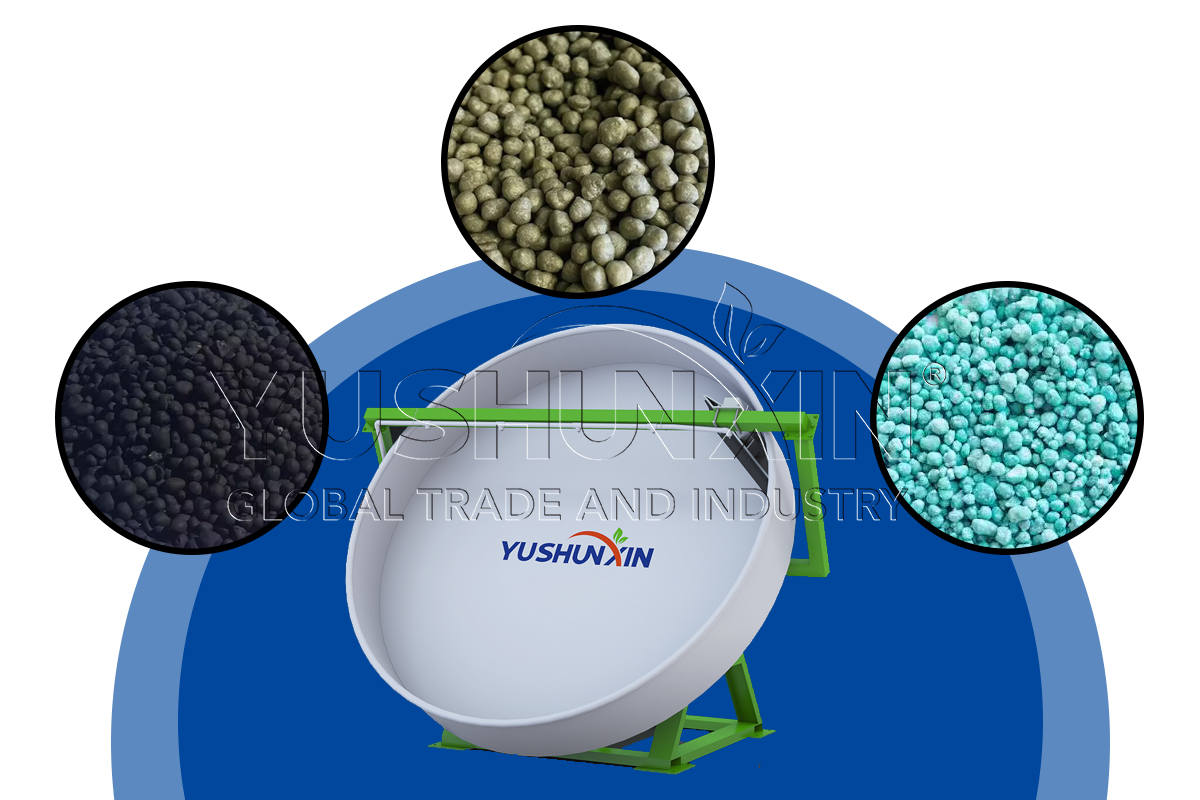

Disk granulator SXYZ-3600 has a diameter 3600 mm. This size makes it ideal for working with large volumes of materials. Larger diameter not only increases performance, but also enhances the effect of mixing and granulizing materials in the plate. It means, that the granulator is able to process more material in one operation. General performance is increasing, and the number of necessary operations is reduced. Suitable for mass production of pellets.

What is the height of the side of the dish?

The height of the frying pan - 450 mm. This design takes into account the movement of materials in the bowl and safety in the granulation process. The moderate height of the sides guarantees, that the material will not be easy to get enough sleep when rotating at high speed. At the same time, it provides enough space for uniform distribution and granulation of materials. A higher edge also reduces the waste of the material, making the granulation process more efficient and controlled.

What is the speed of the SXYZ-3600?

SXYZ-3600 rotation speed is 13 rpm (rpm). This speed is carefully calculated to optimize the granulation effect. The moderate speed of rotation provides the material with sufficient centrifugal force in the disk for the formation of homogeneous particles. This speed not only optimizes granular efficiency, but also reduces the wear of the machine and energy consumption. What makes it an effective and durable device.

What is the engine power of this model?

Sxyz-3600 melt granulator is equipped with a power engine 18,5 kW. A powerful engine guarantees stable operation of the machine at high loads and provides a constant supply of electricity for the granulation process. Choosing the right engine power, SXYZ-3600 is able to achieve a balance between energy efficiency and performance. This not only reduces operating expenses, but also reduces environmental impact, What makes it an environmentally friendly and economical choice.

What is the production capacity of SXYZ-3600?

SXYZ-3600 performance is from 4 to 6 tons in time (subject). Such performance makes it suitable for large -scale industrial use and can satisfy various production needs. High performance is achieved due to an optimized design and an effective working mechanism. It means, that you can process large volumes of material in a shorter time, Increasing productivity and profitability.

What type of gearbox is used in SXYZ-3600?

SXYZ-3600 uses gearbox type ZQ400. This gearbox is well known for its high efficiency and durability. Can guarantee, that the machine will maintain stable operation in various operating conditions. The choice of the gearbox directly affects the overall performance and life of the machine. The velocity gearbox ZQ400 provides the necessary function of reducing the speed of the machine due to the optimized gear ratio and strong design. Provides a smooth and effective granulation process.

What are the sizes of the SXYZ-3600?

The overall dimensions of the SXYZ-3600 are the length 4100 mm, width 2900 mm and height 3800 mm. These sizes make them suitable for installation in various industrial conditions. Despite its large size, It was developed for easy integration and installation. The well -thought -out design not only saves place, but also ensures the convenience of operation and ease of maintenance.

Is SXYZ-3600 suitable for all types of materials?

The SXYZ-3600 disk granulator is designed for processing of a wide range of materials. However, to ensure optimal performance and avoid potential compatibility problems, we recommend that you consult with us before use. The physical and chemical properties of various materials can affect the results of granulation, Therefore, it is important to understand the scope of equipment. It also helps to extend the life of the equipment and reduce unnecessary wear.

What service is necessary for optimal performance?

To ensure the best productivity of the SXYZ-3600 plane, regular Maintenance. General maintenance measures include:

- Check the engine and gearbox: regularly check the working condition of the engine and gearbox, To make sure of their normal work.

- Lubricate moving parts: All moving parts must be regularly lubricated, to reduce friction and wear.

- Clean and inspect the equipment: Regularly clean the pallet of the remains of materials and check the wear of the equipment. Replace damaged parts immediately.