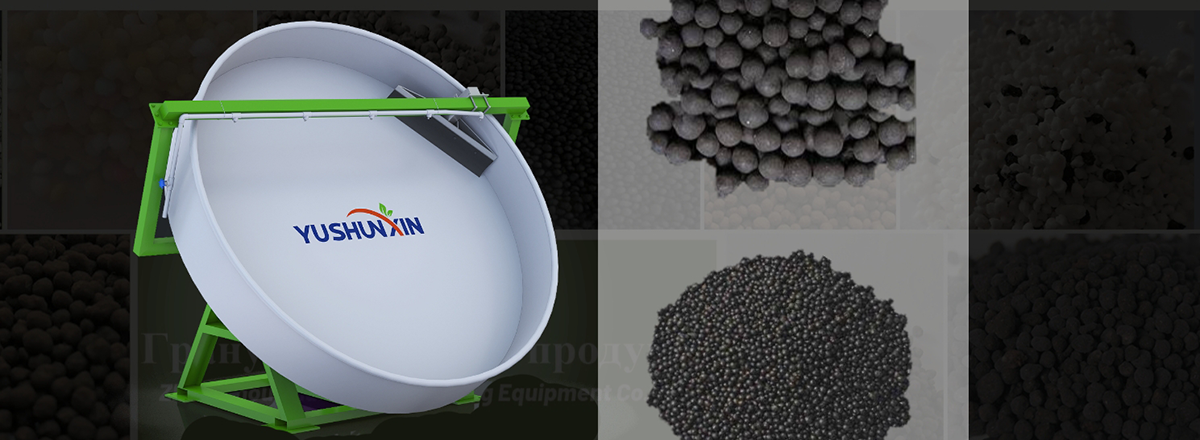

Recently we began in -depth cooperation with Tim, Client from the south of England. Tim hopes to process the powder of brown coal into pellets for more efficient use in agricultural production. Its specific needs include the production of bulky pellets with a diameter of 3-4 mm for agricultural use. And the brillon of brown coal measuring 1.5–2 mm are used to care for excellent lawns, For example, on golf fields. Such requirements require not only a high degree of flexibility of equipment for granulation. It is also necessary to maintain efficiency and stability during the production process. After a detailed analysis of needs and technical assessment We recommended Tim Disk granulator SXYZ-2800. And helped him achieve outstanding success in real production.

Why do we recommend the SXYZ-2800 disk granulator to this British client for granulation of brown coal?

First of all, Disk granulator SXYZ-2800 It has a processing performance 2-3 Tons per hour. This fully provides the customer's needs for brown granules in the production of granules. The remarkable flexibility of our disk granulators allows them to simultaneously produce brown -round pellets of different sizes. This is especially important for customers, which needs to be made by brown -angle pellets with a diameter 3-4 mm and 1,5-2 mm. Clients can accurately control the final size and quality of particles, adjusting the angle of inclination and speed of disk rotation. Besides, The disk granulator has a simple design, convenient in operation and maintenance. This significantly reduces the costs and time for operators training.

What are the advantages of our disk granulator in the production of brown coal granules, corresponding to customers' needs?

Accurate particle control: adjusting the angle slope And the speed of the disk rotation, the final size of the particles can be accurately controlled. Can satisfy a variety of needs for 3-4 mm and 1,5-2 mm. Such flexibility is especially important for customers with various needs, Such as Tim.

Construct with several outputs: To satisfy the requirements of the client of Tim for various particles, We have developed several issues for the SXYZ-2800 disk granulator. Separation and collection of particles of brown coal of different sizes can be achieved by simple configuration settings.

Effective production capacity: The optimized design design provides high production efficiency and the quality of the particles. Satisfy the needs of mass production. This allows British clients to receive large volumes of high -quality granular products during a short production cycle. Increased production efficiency and competitiveness in the market.

Client of Tim after a month of using a disk granulator.

After the successful installation and use of the SXYZ-2800 disk granulator, Tim is very pleased with its work. He successfully produced Brown coal particles 3-4 mm and 1,5-2 mm, who met the requirements, and introduced them on the market. Burrent granular organic fertilizer size 3-4 mm is successfully used in large -scale agriculture. Small particles in size 1,5-2 mm received positive reviews in golf and gardening fields.

This decision not only helped Tim to expand the line of its products and attract more customers and opportunities for business in the market, but also significantly increased its competitiveness in the market in the field of sustainable agriculture.

Customer raw materials are tested at our factory.

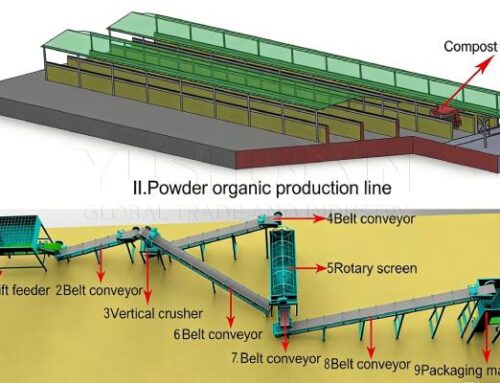

In addition to granulators for granulation of brown coal, We can also provide you with lines for the production of organic fertilizers from brown coal. If you are interested Brown coal -coal fertilizer production line, Please, Contact us to get additional information. Our team will provide you with detailed information about the product, technical support and individual solutions. To satisfy your specific needs. We hope for cooperation with you and the provision of the most high -quality equipment and services for your production.