Equipment for mixing, necessary for the production of mixed fertilizers

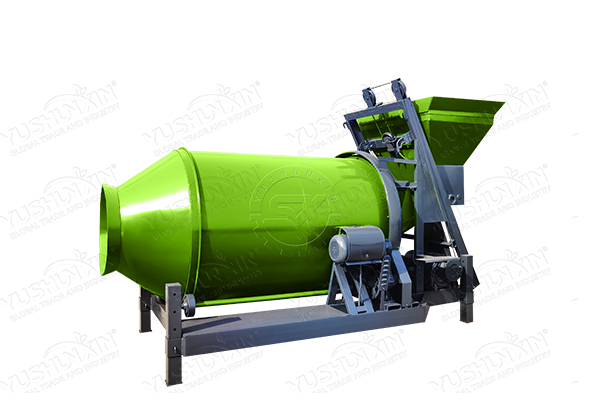

BB Fertilizer mixer

- Performance: 1-20 (subject)

- Type of equipment: Mixing equipment

- The materials used: Fertilizers BB/mixed fertilizers

- Brand: Shunxin Machinery

- Product: Absolutely new

- After -sales service: Setup, installation, Debugging, Technical leadership

- Technical leadership: Support

- Setup: Yes

- Direct sales from the manufacturer: Yes

BB fertilizer mixer specially designed for the BB fertilizer production line. He is used to mix complex fertilizers, containing nitrogen, phosphorus, potassium and trace elements. Passing it is used in the production of complex fertilizers, It is also called mixers for complex fertilizers. This equipment is ideal for mixing finished granular fertilizers.

Our mixer eliminates the phenomenon of chromatography or shunting, arising when mixing your materials due to different specific weight and size of particles of raw materials. Moreover, it also eliminates the impact on the mixer system, caused by such factors, as characteristics of the material, Air pressure, Stress and cold weather, so that your production could be more smooth.

The main design of the mixer for fertilizers BB is the lifting system, High -precision mixing system, Storage rack, Electric control system and t. e. This is not only a new design, High practicality, but also small investments and a flexible formula. This is the best choice for you, to produce mixed fertilizers.

· Fertilizer production line BB.

What are the requirements of the BB fertilizer mixer to your raw materials?

This mixer requires the same size of particles of raw materials, which you use to mix fertilizers. It not only requires, so that the upper and lower limits of the size of the particles are the same, But also demands, so that they have the same distribution of particles. Therefore, you must analyze the distribution of particles of various raw materials before mixing. This is the only way you can be sure, that fertilizer, which you produce using a mixer for BB fertilizers, will be of high quality.

What material do we use, to make a qualified mixer for BB fertilizers for you?

The main body of the mixer for fertilizers BB is made for you from the industrial stainless steel. At that time, how internal cladding is made of stainless steel isolation technology. This can prevent your raw materials from corrosion of the machine and extend your car service life.

For the control system for the BB fertilizer, we use Secondary anti -seismic protection and technology of multi -stage filtration. He can not only adapt to various harsh conditions, but can also provide measurement accuracy. Make sure, that products, which you produce, are high -quality products.

How our mixer for fertilizer BB works?

He can work as in direct, and in the opposite direction. Complete the dosage of fertilizers, which must be dosed and mixed. It is sent to the mixer mixer with a bucket elevator or conveyor tape conveyor. The mixing tank rotates clockwise, and the lifting platform continuously raises, rolls and lowers the fertilizer inside. Apil the goal of mixing particles for you. Then turn the mixing tank counterclockwise, To unload the material, and then make packaging.

We provide you with two BB fertilizers of different performance!

We have two types of BB fertilizers with different performance. This is equipment, developed in accordance with various technological capabilities and scale of the BB fertilizer production line.

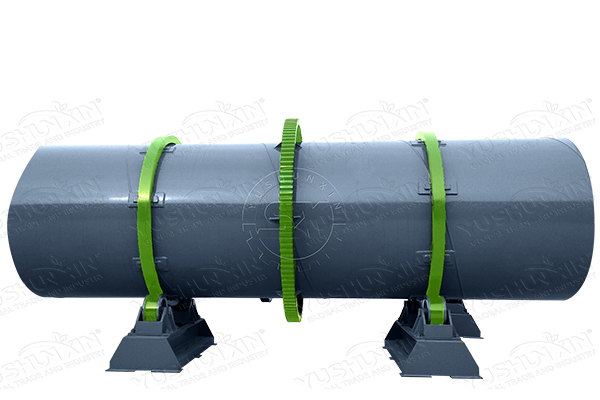

Big Fertilizer Mixer BB:

This type of mixer is usually used on large -scale production lines. He can process dozens and hundreds of tons of raw materials. Large mixers have a larger volume and stronger mixing possibilities. Usually equipped with an effective drive system and durable mixers. Ensure good mixing efficiency and stable work at high load. Besides, We will provide you with advanced control systems to automate operations. Increase the efficiency of the production of fertilizers BB and reduce labor costs.

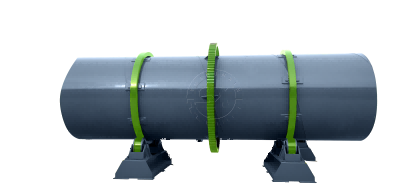

Small Mixer Fertilizer BB:

For small-scale production or research work, a more suitable choice will be a small BB fertilizer mixer. These mixers usually process the volume of raw materials from tens of kilograms to several tons. Due to the smaller size, they are more universal, Easy in operation and maintenance. Small mixers are enough to meet the needs of small production lines or laboratories, At the same time, occupying a small area. You can move it at any time depending on your production needs.

Big is or a small blender? The key point is the choice of equipment, which corresponds to the scale of your production and needs. Ensure production efficiency and product quality. In this case, the design of the mixer should also take into account the physical properties of raw materials, Such as viscosity, Density and fluidity. To guarantee, that various types of raw materials can be effective and evenly mixed. Tell us your data, and we will develop equipment for mixing bb fertilizers, which is best suited to you!

How many fertilizers can mix for you a fabric for fertilizers BB per hour?

We have four models of BB fertilizers for your choice. 1-20 subject, and one mixing can be completed for 3-5 minutes, which can satisfy the requirements of various small and large enterprises.

Machine mixer fertilized BB GJB-1200, Productivity 1-2t/hour. We have accepted for you an automatic dispenser ZP1200 and an automatic dispenser and packaging machine KH-ZL-50, which are suitable for some small factories. If your weekend requires is small, You can choose this option.

If you need equipment performance 3-5 subject, You can choose GJB-1500. This is equipped with an automatic dosing device ZP1500 for you. If you want to achieve performance 5-10 subject, You can equip the GJB-1800BB fertilizer mixer, which is equipped with an automatic dosing device ZP2000.

The aforementioned faucets are equipped with an automatic dosing packaging machine KH-ZL-50 and the SX-500 model tape conveyor, so that you can better do the mixing work.

If your factory is a large -scale and should achieve more performance 10 subject, You can choose a GJB-2000BB fertilizer mixer, equipped with an automatic dosing device ZP2300, which can satisfy your needs for great performance. If your performance needs exceeds 20 subject, You can equip several more mixers for GJB-2000 BB fertilizers.

The aforementioned faucets are equipped with an automatic dosing packaging machine KH-ZL-50 and the SX-500 model tape conveyor, so that you can better do the mixing work.

Why do many customers choose our mixer for BB fertilizers?

High accuracy of ingredients.

In our mixer for BB fertilizers, secondary mixing technology is used. Eliminates the adverse effects of various proportions of materials on the ratio of products and guarantees the production of high -quality products.

The equipment is of high quality.

For electronic control system A fertilizer mixer of fertilizer mixer BB tools and other components are sealed, to prevent fertilizer dust corrosion. Extend your life for your equipment.

High performance.

Our BB fertilizer mixer is equipped with a consumption regulator, so that you can carry out dynamic and continuous measurements in accordance with your various performance requirements. Besides, The use of the stream management system makes the overall design of the mixer more compact and durable, What makes your work more convenient and flexible.

If you intend to buy our mixer for BB fertilizers, What is its sale price?

What key equipment do you need in the process of manufacturing BB fertilizers, In addition to BB fertilizer mixer?

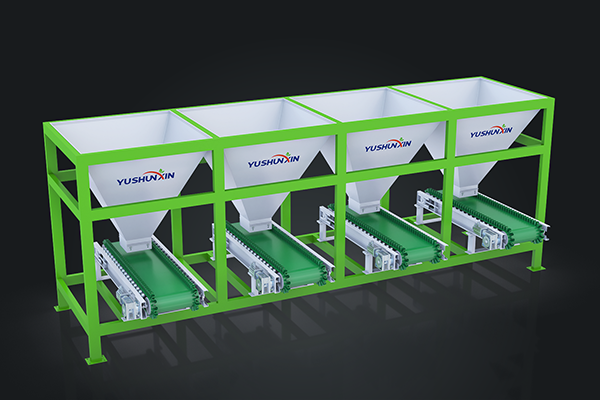

Automatic dosing warehouse. In the process of production of fertilizers, the BB warehouse of ingredients plays a vital role. Dosage warehouse, which is the key component of the BB fertilizer production line, is responsible for storage and preliminary mixing of various raw materials. Provide you accurate dosing and continuous supply of material. These warehouses are equipped with complex control systems, which allow you to accurately weigh and distribute various raw materials. This guarantees the quality and stability of the final product.

Doster warehouse not only increases the efficiency of the production of fertilizers of BB, but also reduces the complexity of employees. Thanks to automated control, errors are significantly reduced in the process of manufacturing BB fertilizers. In the process of production of fertilizers BB, Whether it is small or large -scale production, The ingredient warehouse is your key object, allowing to ensure product standardization and increase competitiveness in the market.

If you want to know more about the BB fertilizer mixer, You can leave your contact information, And we will contact you during 24 hours. We have many years of experience with bb fertilizers production lines. Designed and built production lines for the production of BB fertilizers for many customers. Welcome, Contact us, To get the relevant videos, Images and other information. Besides, We also have NPK production line, liquid fertilizer production line and other fertilizer production lines.