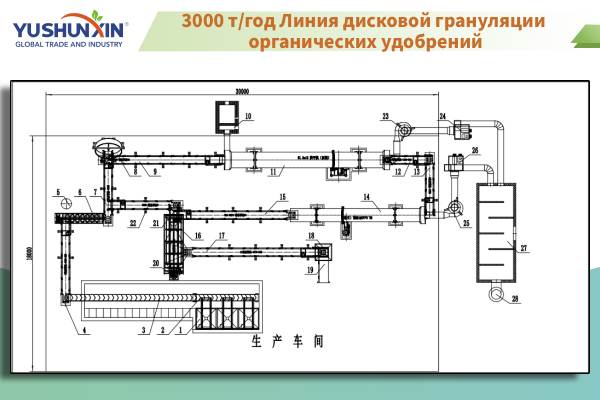

3000 t/year The organic fertilizer disc granulation line is designed for highly efficient production of granular organic fertilizers with an annual output of up to 3000 ton. Main equipment includes:

- Feeder with bucket loader 2030 — ensures a uniform supply of raw materials, guaranteeing stable operation of the entire line.

- Belt conveyor B500-7m — transports raw materials to the next stage of processing.

- Vertical crusher 600 – effectively crushes organic materials, ensuring their homogeneity for subsequent granulation.

- Belt conveyor B500-8m — connects the crusher and the primary screen.

- Bolt 1030 - carries out preliminary sifting, removing too large or small particles.

- Belt conveyor B500-7m — supplies sifted raw materials to the disk granulator.

- Disk granulator 2000 — main unit of the line, forming uniform granules from prepared raw materials.

- Belt conveyor B500-11m – transports granules to the secondary screen.

- Bolt 1240 – carries out repeated sifting to ensure the quality and uniformity of granules.

- Belt conveyor B500-10m — transports finished products to packaging equipment.

- Packaging machine — automates the process of filling and packing granules, increasing efficiency.

- Electrical control cabinet — carries out centralized line management, provides security and monitoring.

- Self-propelled compost turner — used at the composting stage to uniformly mix raw materials and accelerate fermentation.

This plate granulation line features a high degree of automation, rational equipment configuration and can be used for processing various organic wastes into high-quality granular fertilizers. The solution allows you to effectively reduce labor costs, increase productivity and ensure consistent product quality.

- Rich Experience: many years of experience in the industry, streamlined and efficient processes.

- Modern equipment: high-precision equipment to improve product quality.

- Team professionalism: excellent professional abilities, allowing you to quickly solve problems.

- Quality assurance: products are certified according to ISO standards, CE, ANAB, IAF and other international standards, which guarantees its safety and reliability.

- Thoughtful service: from consultation to after-sales service, with fast response.

- Flexible setting: Various customization options to meet different needs.

We prioritize customer satisfaction and provide comprehensive after-sales support, to ensure stable and efficient operation of your equipment. Our after sales services include:

- Installation and commissioning: our engineers will come to you to install and commission the equipment, ensuring smooth operation.

- Technical training: Systematic staff training helps operators master the equipment.

- Supply of spare parts: sufficient quantity of original spare parts to ensure timely replacement.

- Remote support: Technical support is provided through various channels, including telephone and video communication.

- Emergency response: 24/7 hotline for quick response.

Contact us now and get a discount up to 30%. Send an email for consultation right now!